Fly away: Producing planes in Pakistan

CEO of the only lightweight aircraft maker in the private sector says he has identified a market already.

In an increasingly fast paced world, CEO of the only lightweight aircraft maker in the private sector says he has identified a market already.

Or so goes the saying, one that thirty-eight-year old Faisal Naveed Asif firmly believes in.

“There will always, always be people who need to travel fast,” says the CEO of Scaled Aviation Industries, the only lightweight aircraft maker in the country’s private sector, as he recalls the example of a Lahore-based surgeon who wanted to visit patients in rural Punjab and be back home by the evening. “We have identified a market which is just going to [keep growing].”

Forging sky tracks

In a country that has seen its fair share of airlines starting with pomp and fanfare but going down quickly, Asif seems to be made of a different mettle. For him, the business is all about understanding, patience and commercial viability.

“In key cities, like Karachi and Lahore, the traffic chaos is becoming unmanageable,” he says. “And we realise that. Our planes cost between $120,000 and $170,000. If you compare it [a plane] with some of the luxury cars people are buying, it is actually cheaper.”

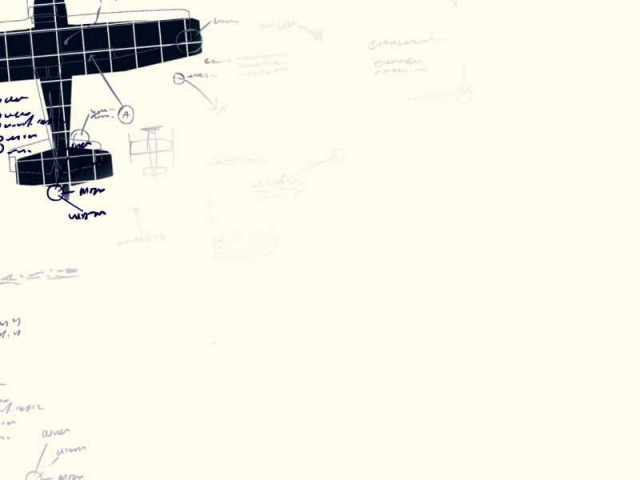

Made from composite material, a small two-seater aircraft weighs around 230 kilogrammes. It is designed to land on any flat surface and does not require a proper runway.

According to Asif, the fuel efficiency of his company’s Bombardier Rotax engine-driven plane, built to run on petrol, is more than the Cessna. After the company started marketing its planes in 2009, it has been making sales regularly.

Scaled ambitions and pointed limitations

“We are making 23% of the airframes locally,” he says. “This includes landing gears, internal seating, flaps and other components.”

Soon, as part of the deletion programme – which means slowly developing the capability to manufacture more parts locally – Asif intends to make the entire aircraft frame in Pakistan.

However, he cautions against anticipating miracles.

“To expect that we will start making engines here is out of the question. A thing as complicated as an aircraft engine needs 30 to 40 associated industries and years and years of work. We don’t even have a metallurgical base for that at the moment,” he remarks.

Asif also elaborates upon the difficulties associated with setting up a business in Pakistan and basing designing in house.

“Even for the designing phase, you need an investment of Rs22 million. This is just for setting up a design organisation,” he says. “[Then], if a wing weighs 50kgs, I have to get 150kgs of paperwork done to design it here.”

Scaled Aviation manufactures and markets the aircraft under licence with Kolb, which has been acquired by ATR Aircraft.

“Under the agreement with Kolb we have access to every kind of data on design, engineering and tests. We have all the information on the aircraft,” Asif explains.

In total, he estimates, designing and then testing an airframe costs around $8.5 million. “I didn’t have that kind of resources so I opted for this joint venture,” he says.

Making of the man

Asif has not fallen into this career – it’s no fluke, but a passion he has carefully nurtured over the years. His journey began from Quetta, where he spent most of his life. “As a kid, I was part of a flying school,” he says. “From there on, the love for planes remained with me.”

Armed with a PhD in engineering, Asif worked with defence industry for 11 years before venturing into the business of making aircraft. “Over the years, I had developed expertise in the field,” he explains. “It was natural for me to do this.”

Published in The Express Tribune, July 18th, 2013.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ