According to the official, the managing director (MD) of the Nandipur project should have, as a first option, considered tasking his own men with running the plant. Barring that, he could have either engaged an engineering, procurement, and construction (EPC) contractor or asked General Electric (GE), the manufacturer of the plant, to operate it in the short term.

Instead, the project chief, who has been appointed by the Punjab government, decided to choose the last option among the four provided to him ranked in terms of feasibility and cost, and invited bids for a long term contract to maintain and operate the plant.

A Malaysian firm emerged as the successful bidder because it was the single party that made the offer. However, the board of directors of Nandipur was concerned at the rates quoted by the Malaysian company, which forced it to scrap the tender. The board noted a number of issues in the process like post-bid changes, paying more to the contractor than what the plant will receive from the National Electric Power Regulatory Authority (Nepra), and an open-ended contract for nine years of the proposed contract period.

The official, speaking on condition of anonymity, said that the MD also wanted the water and power ministry to approve awarding operation and maintenance of the project to the Malaysian firm while bypassing the project’s board of directors and responding to the questions raised by the board. The official said that hiring a Chinese EPC contractor was the second option which the MD should have explored if he had given due consideration of all options before selecting the last one. He said a draft agreement had been given to Dongfang to sign a short-term deal for operating the plant before international competitive bids are awarded. The EPC contractor is bound to provide all equipment related to the power plant. It has submitted a $35 million guarantee and if it is found to be irresponsible, the guarantee may be encashed.

Nandipur power company’s MD Captain Mahmood defended his decision to hire a long-term operator and blamed the project’s board of directors for delays in awarding a contract towards this end to the lowest bidder. “I wrote dozens of letters to the power ministry, asking it to intervene in the affairs of the board which did not take timely decisions,” he said, denying that he asked the ministry to approve the project by bypassing the board.

Asked about the first option of using his own team to run the plant, Capt Mahmood said, “Everyone knows how Gencos (power generation companies) are being run… It was not a good idea to have a local workforce operate the Nandipur plant.”

Regarding the third option of having GE run the plant in the short-term, he said the US-based conglomerate was only a manufacturer, not an operator of such plants. “In any case, we couldn’t award a short-term operation contract to GE without an open bidding process,” he added.

“The best option was to hire a long-term operator,” Captain Mahmood maintained, saying the move was even approved by Minister for Water and Power Khawaja Asif. He added that Dongfang Electric Corporation had now been hired due to an emergency clause, but pointed out that the Chinese EPC contractor has no experience of running power plants.

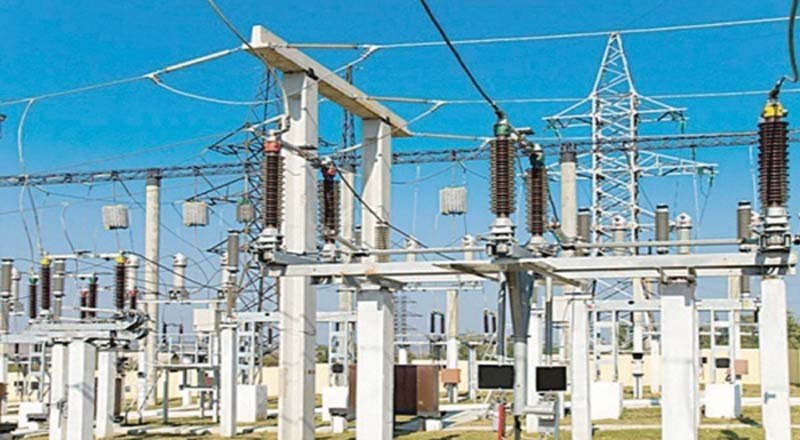

The main problem with the tri-fuel Nandipur power plant is the low capacity of the furnace oil treatment plant, which has created hurdles in the way of operating the power plant at full capacity, the official explained.

The Nandipur power plant requires a furnace oil treatment plant with an annual capacity of 30 million tons, but the current treatment plant only has the capacity to process 19 million tons. Now the EPC contractor is making arrangements to enhance the capacity of the treatment plant at its own expense to meet this obligation. The official said that Dongfang had also given operation and maintenance rates that have been submitted to Nepra.

Published in The Express Tribune, October 12th, 2015.

1725967717-0/Untitled-design-(3)1725967717-0-405x300.webp)

1725275251-0/Untitled-design-(3)1725275251-0-165x106.webp)

1720097164-0/BeFunky-collage-(9)1720097164-0-165x106.webp)

1730547935-0/Untitled-design-(5)1730547935-0-270x192.webp)

1730544105-0/Untitled-design-(87)1730544105-0-270x192.webp)

1730543683-0/Express-Tribune--(3)1730543683-0-270x192.webp)

COMMENTS (7)

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ