Drink it, wear it: Wake up and smell the coffee

Fabric that incorporates coffee grounds has become a global hit.

Taiwan’s once-booming textile industry entered this decade in need of a wake-up call, with global competition having reduced exports by over a third. But one firm has received a boost from a surprising source: coffee.

The S Cafe fabric, made by small firm Singtex Industrial, incorporates recycled coffee grounds from Starbucks and 7-Eleven, and has proved a hit with heavyweight international brands including Nike and North Face.

Industry figures say the fibre -- more than three years in development, and sold under the slogan ‘Drink it, wear it’ -- shows how the sector might reinvent itself as green, savvy, and even cool.

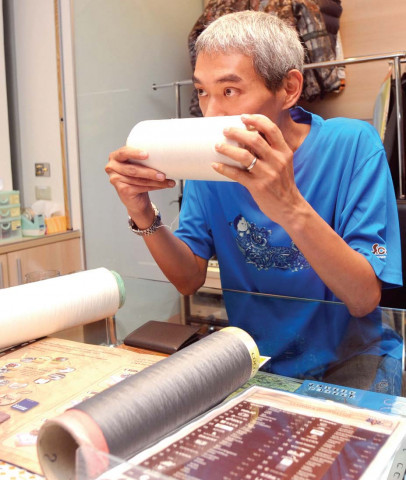

“S. Cafe fibre marks a technological breakthrough in the company’s research and development,” said Jason Chen, the company’s 50-year-old chairman, who drinks four cups of coffee a day.

Taiwan’s textile exports peaked in 1997 with a value of $16.7 billion, but since then, overseas shipments have been declining, as the island’s wages have gone up while tough and nimble rivals have emerged in China.

Partly due to the global crisis, exports hit a nadir of $9.4 billion in 2009, according to figures compiled by Taiwan Textile Research Institute, a semi-official industry research unit.

Yet Frank Hsu, deputy secretary-general of the Taiwan Textile Federation, insists this is not the end of the story.

“The textile industry is by no means a ‘sunset industry’,” he said. “Rather, the sun is right above our heads.”

The island’s textile sector, in which 4,000 companies now employ some 190,000 workers, needs a renaissance, but it may not be easy -- and it definitely will not be cheap.

Singtex spent Tw$50 million ($1.7 million), or around one third of its capital, to develop its new fabric, which contains about two percent coffee extracts, with the rest polyester or nylon. But the investment has paid off.

S. Cafe revenues came in at around Tw$100 million in 2010, and sales from fibre-related businesses have hit Tw$170 million in the five months to May, accounting for 20 percent of the company’s revenues.

The addition of coffee grounds helps to control odours and protect against UV rays, as well as enabling the fabric to dry faster. But too much would make the fibres snap easily - meaning the process had to be finely calibrated.

The results have created a buzz. US outdoor footwear and apparel giant Timberland describes a jacket using the fabric as “our most environmentally conscious performance jacket ever”.

Altogether, Singtex supplies fabric to nearly 70 globally noted brands, from Germany’s Puma to Japan’s Mizuno.

Its secret was to help those firms make environmental concerns part of their corporate image.

“This is a smart marketing strategy. It speaks directly to the hearts of environmentally conscious consumers,” said Yin Cheng-ta, an official from the Taiwan Textile Research Institute.

As the industry seeks fresh vitality, Singtex’s success is remarkable, but not unique. Inventiveness has become a necessity for companies who have not moved their production to low-cost areas in China and Southeast Asia.

Several firms have branched out into creating fine fibres, with companies including Nan Ya Plastic Co., Zig Sheng Ind Co and Chain Yarn Co producing yarns with less than five deniers -- compared with a normal 75 deniers.

“Cloth made of such yarns is so fine that it is usually described as ‘second skin’ - it’s almost like the skin of babies,” Yin said.

Cloth made of such fine yarns sells for around five US dollars a yard, compared with 1.0-2.0 US dollars for normal cloth.

But the dyeing and manufacturing processes are so demanding that only a few countries, such as Italy and Taiwan, produce the cloth, he added.

Published in The Express Tribune, July 11th, 2011.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ