Trending footwear: Handmade still defines luxury for the capital’s endowed

Workers say machines and quest of business owners to maximise profits has seen quality decrease

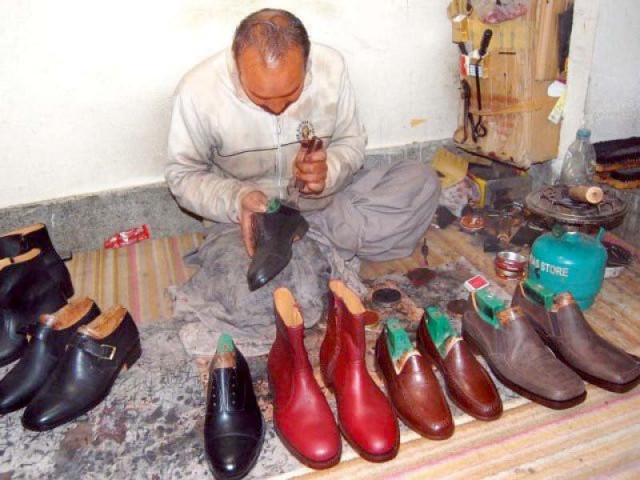

A shoemaker gives final touches to shoes at his workplace. PHOTO: EXPRESS

At one point in time, handmade leather shoes of Pakistan used to be popular and sought after commodities across the world. But with the rise of western fashion brands coupled with a failure to evolve diminished the appeal of these shoes.

Adeel, a shoemaker, stated that Pakistani leather goods are famous all over the world including jackets and handmade shoes because of the availability of high-quality leather here.

He added that he used to have a store in Rawalpindi, but due to its success he was able to expand his business to Islamabad for better prospects.

New master plan in Islamabad to resolve citizens’ issues

His store is among others for handmade shoes in the Jinnah Super Market along with stores in Sectors F-10 and F-11.

They claim to regularly receive large orders for handmade shoes, especially from the contingent of foreigners who work at the different embassies in the federal capital.

Adeel said that because they have all the available tools, they are able to make any kind of shoe desired by their customer, including from pictures which a client brings from the internet. He adds that it usually takes them two to three months to complete a consignment of custom-made shoes and that they charge between Rs10,000 to Rs15,000 per shoe.

Asked about the variation of the requests they get for custom shoes, he said that some of their customers request for shoes to be made from exotic materials including crocodile or tiger skin.

“The government has placed a strict ban on the use of crocodile and tiger skin-shoes and has also warned shop owners of heavy fines if these skins are recovered from their establishments,” Adeel said, adding that even if a customer promises to provide them with the contraband materials, they turn such customers away.

Anwar, a craftsman who works at a workshop of one of the custom shoe establishments, said that he has been preparing handmade shoes for the past 60 years.

Having seen the rise and then the fall of the leather goods industry of the country, he said that they, their craft and their livelihoods were under threat from the import of cheap Chinese machines.

“Machine-made shoes are preferred by shopkeepers due to their cheap cost and high-profit margin,” he stated, adding, “However, those shoes are made from poor materials.”

He added that more and more shoe factories and workshops across the country were now turning to these machines to maximise their profits.

Asked about the process of making shoes by hand, Anwar says that they receive soles as sheets. They cut out the desired shape of the sole from a machine. After that single use of a machine, Anwar says they use only their hands and manual tools to make the rest of the shoes.

Discussing the process, he says that the sole is stuck to the upper section of the shoe and then the shoe was affixed to a wooden frame of the desired size.

While pointing out the difficulties faced during the crafting procedure, he said that they use a lot of glue in the process and have to spend an extended period of time in their fumes as the glue dries.

To dry the glue faster, they have to use a fan, even during the extremely cold winter season.

The ‘cave people’ of Rawalpindi

“If we do not use a fan to dry the glue, we would only manage to complete a few pairs of shoes a day,” he said, adding that they have to inhale the strong fumes of the glue which causes them headaches at night.

However work ebbs and flows, Anwer says, adding that they are usually paid daily-wages between Rs600 to Rs800 instead of per shoes and that they are only paid a monthly salary when work is in full swing.

But with handmade shoes going out of fashion, their fortunes also faced a dip and they faced complications in managing their household expenses.

But with some businesses bringing handmade and custom showed back into fashion, including promotion of the products internationally, he hopes that the industry will pick up once again.

Published in The Express Tribune, February 6th, 2019.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ