Garment manufacturers: Heavy taxes hamper investment in sophisticated machinery

Big businessmen go overseas, small ones reluctant to pay high prices.

Garment manufacturers: Heavy taxes hamper investment in sophisticated machinery

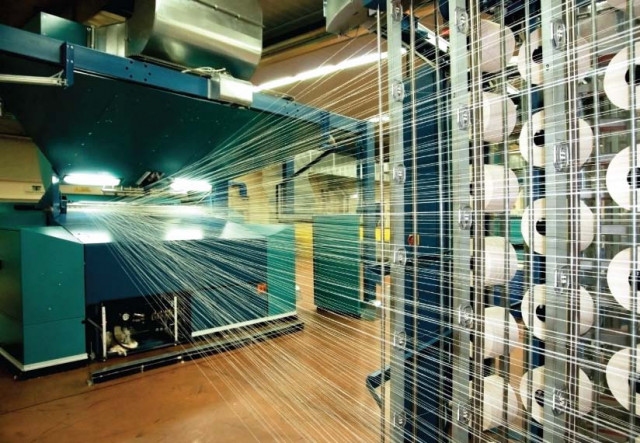

In fact, industry experts had foreseen the sharp decline in export volumes because of two reasons: one, the lack of investment in imported garments machinery from 2008 onwards; and two, the rising trend of shifting manufacturing operations from Pakistan to Bangladesh.

Al Murtaza Machinery Company Private Limited – which imports knitting, cutting, stitching, embroidery, finishing and quality testing machinery from Japan, China, Europe and the US – has lost more than 50% of its business since 2005, according to its Chairman Asif Ali Rashid.

“We’re heavily taxed. On every machine we import, we pay customs duty at 5%, sales tax at 19%, income tax at 5% and clearing, transportation and terminal charges at 3%,” Rashid said.

Pakistan’s oldest commercial importer of garments machinery, Rashid says Al Murtaza Machinery still holds market shares of 60% and 18% in terms of value and volume, respectively. Yet, the company’s sales force decreased by 40% between 2008 and 2011.

Highlighting the fallout of the sales tax, which is imposed on commercial importers only, PRGMEA Research Officer Ibrahim Mahmood told The Express Tribune that while big manufacturers had been shifting their operations to Bangladesh, small and medium-sized businessmen were reluctant to pay increased prices.

“Small buyers aren’t able to import machinery themselves. No wonder little investment is taking place in the garments industry today.”

Analysts believe that the process of value addition, which can be defined as the enhancement added to a product or service before it is offered to customers, is central to garments manufacturing, as the price of a value-added product can sometimes be 400% higher than that of a basic product.

“In some cases, the cost of a sophisticated machine that produces complicated garments can be 250% higher than that of a basic machine. But it is one-time investment,” Rashid said.

While a simple pair of jeans can be sold at $6, a fancy version of the same product, prepared with the help of a sophisticated machine, can fetch as much as $18 per piece, he added.

“There’ve been examples where output has increased by 100% because of bringing sophisticated machinery online. But who’ll make the investment when banks charge 18% interest rate and imported machinery is taxed so heavily?”

Speaking on condition of anonymity, another leading importer of apparel machinery, who has offices in Karachi and Lahore, said the profit margin in the industry had decreased drastically, especially after 2008. “We’ve operated on a margin of up to 15-20% in the past. Now it’s somewhere around 3%,” he said.

Expressing his hopelessness, Rashid said he had now stopped sending his yearly suggestions to the authorities concerned. “We don’t want a subsidy. All we demand is a level playing field. If you can’t support us, then at least don’t penalise us either.”

Published in The Express Tribune, February 10th, 2012.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ