Unorthodox incubators: Ego invests in entrepreneurial employees

Clothing retailer provides guaranteed business and financing for employees who set up their own operations.

Three years ago, Irshad Ali pitched an idea to his employer. One, he wanted to set up a stitching unit. Two, he wanted his employer to promise him business. And three, he wanted him to invest in his start-up as well.

Ali got all that he wanted. Three years on, he has made a transition from an ordinary skilled labourer working at a stitching unit of a clothing brand to a successful entrepreneur with 18 stitching machines of his own. Ali is now a principal vendor of Ego, a retail clothing brand with 19 outlets across the country.

Interestingly, he is not the only worker who went on to become a full-fledged vendor while working at Ego. Nine out of Ego’s 12 current vendors have been its employees in the past.

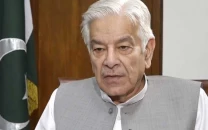

“We always let the employee approach us with the business idea. Entrepreneurship requires risk-taking, and you can’t help a person start his own business unless he’s enthusiastic about it himself,” said Adil Moosajee, owner of Ego, while talking to The Express Tribune.

Explaining the idea of helping employees become independent vendors, Moosajee said his expanding business needed more vendors, and he felt comfortable working with people who were already well-integrated with the company. “There’s less risk involved when you work with a person who already knows your product specifications and quality standards.”

He says Ego matches the number of machines a worker is willing to install by providing him with an interest-free loan. For example, if a worker can set up two stitching machines using his own resources, Ego buys him another two machines. The cost of an average stitching machine ranges between Rs16,500 and Rs22,000.

Investment pays off

The loan is supposed to be returned in three months without any interest/additional charges. Since production orders are already guaranteed by Ego, the investment always pays off. After three months, the vendor is once again eligible to take out another loan and increase his production capacity by 100%.

“We send our project manager to the place where the worker wants to set up his unit. Mostly it’s either in a room or on the roof of his house,” Moosajee said.

He adds that Ego always ensures the electricity connection is legal, and that the unit has an entrance separate from the one being used by the entrepreneur’s family.

This business model is not restricted to the stitching operations only. Company-provided, interest-free loans have also enabled regular workers to become independent printing and fabric vendors.

After paying back the loan in three months, vendors are free to work with any company they want. “However, as long as they’re working with us, we ask them not to work for others in order to maintain our product quality. But if they get more business and better rates from other companies, they’re certainly free to go elsewhere,” he said.

Focus on local economy

For Moosajee, expanding his own business, helping others set up new businesses and thus creating more jobs is not about the bottom line only. “I’d outsource my operations to China or Thailand only if I had no other option left. But let me make it very clear, I’m principally against moving jobs abroad.”

He says there will be massive growth in the economy if each company is able to create at least 10 jobs a year. Comparing multinational companies with yesteryear’s East India Company, he says business graduates should refuse to be a cog in the corporate wheel.

“Become entrepreneurs or join desi small and medium-size enterprises. Create jobs locally, so that wealth can be generated and used within the country.”

Published in The Express Tribune, December 24th, 2011.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ