Furniture industry seeks govt support for better exports

Leading manufacturer says industry lags behind in quality, global standards

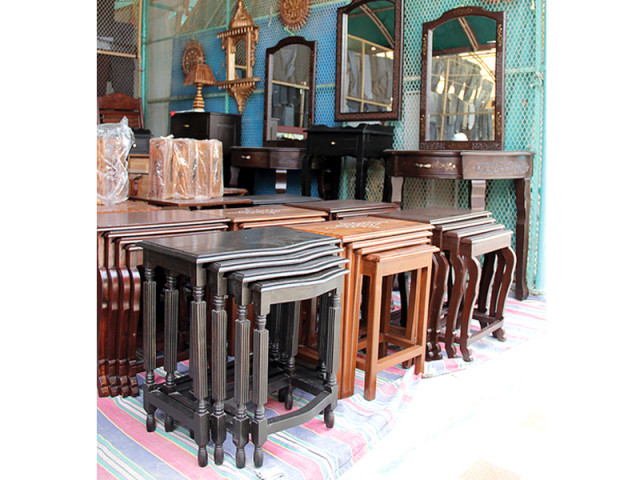

Pakistan's furniture industry, renowned for its craftsmanship and intricate designs, is one of the important sectors, however, despite its potential, the industry is underperforming and facing several challenges that hinder its ability to compete on a global scale.

Pakistan's furniture has a reputation for its unique blend of traditional and contemporary designs. According to people associated with this business, countries like the United States, the United Kingdom and the Middle East present significant opportunities for Pakistan's furniture exports due to the growing demand for handcrafted and customised wooden furniture.

A report of the Pakistan Furniture Council (PFC) says the furniture industry is worth around $1 billion, with exports accounting for only a small fraction of this value.

"Pakistani furniture has its acceptance in leading global markets where handcrafted and wooden furniture has high demand, but unfortunately we lag behind in quality and meeting international standards for better exports," remarked a leading furniture manufacturer while talking to The Express Tribune.

"We have a perfect pool of talent of craftsmen, designers, etc; what we need to do is to align them with global practices."

He said that China, with highly competitive prices, was dominating the global furniture market. However, Pakistan's edge lies in its ability to offer modified designs and handcrafted pieces, something lacking in the mass production of furniture.

European and Middle Eastern countries, in particular, are seeking more high-end, customised pieces, creating a niche that Pakistan can capture.

Local manufacturers face many other hurdles that limit their competitiveness on the global stage. Rising costs of raw material, especially wood, and a lack of modern machinery are the two primary issues. The industry relies heavily on imported machinery, which increases production costs and reduces profits of manufacturers.

"Lack of advanced machinery and high raw material costs are major barriers. If we don't modernise our production methods, we'll be left behind in global competition," said Muhammad Kamran, a furniture manufacturer from Chiniot, a hub for wooden furniture.

Additionally, high energy cost and inconsistent power supply continue to impact the industry. Small and medium-sized enterprises (SMEs), which make up a significant portion of the furniture industry, often lack resources to invest in power supply backups, which disrupt production timelines.

"The furniture industry is largely dominated by SMEs and they simply do not have the capacity to deal with issues like power outages. It directly affects our output and our ability to meet deadlines, both locally and internationally," said Ali Hamza, a furniture exporter from Lahore.

"We need streamlined export processes and government support to compete internationally. Many manufacturers don't have the expertise or resources to navigate international trade regulations on their own," Hamza added.

Furniture exporters said that to fully capitalise on the export potential, the industry needed significant modernisation. Investment in machinery, technology and design innovation is critical.

They believe the government should play an active role in facilitating this transformation by offering subsidies for machinery import and encouraging public-private partnership to train the workforce in advanced manufacturing techniques.

"There's a global demand for the type of craftsmanship we produce. With the right kind of support from the government in terms of subsidies and modernisation initiatives, Pakistan could become a major player in the international furniture market," Hamza said.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ