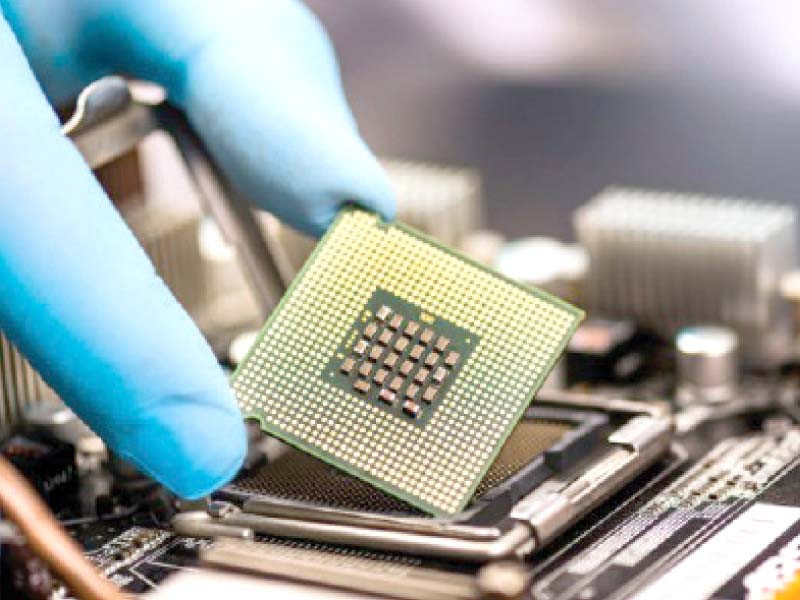

Malaysia’s help is needed to resolve the global shortage of auto semiconductors, especially when it comes to packaging, a sector affected by the country’s Covid-19 curbs, Taiwan Economy Minister Wang Mei-hua said.

Taiwan, as a major chip producer, has been front and centre of efforts to resolve the shortage, which has idled auto plants around the world.

Speaking in an interview, Wang told Reuters that Taiwan alone could not sort out the problem because the supply chain is so complex.

“The bottleneck in fact is in Southeast Asia, especially Malaysia, because for a while the factories were all shut down,” she said.

The problem was especially acute with auto chip packaging, with companies in Malaysia providing services not offered by Taiwanese firms, Wang added.

“Now the focus is on Malaysia resuming production as soon as possible.

I know that Malaysia started to restore production capacity in early September, and now the production capacity has returned to about 80%, so if their capacity can slowly come back, this problem can be slowly dealt with.”

Malaysia is home to suppliers and factories serving semiconductor makers such as Europe’s STMicroelectronics and Infineon, as well as major carmakers including Toyota Motor Corp and Ford Motor Co.

Malaysia Semiconductor Industry Association President Wong Siew Hai said that the major Malaysian semiconductor manufacturers are already running at full capacity to supply the auto industry.

“For the automotive chips, they are doing their best to ship as much as possible, but the current capacity cannot meet demand because it is too huge, the build-up is a lot,” he said.

“Everything is at 100% to satisfy the demand for automotive parts. Where they can increase productivity, they are already doing so.”

Adding capacity will take time, with most available only next year, Wong said.

Malaysia accounts for 13% of global chip packaging and testing, and 7% of the world’s semiconductor trade passes through the country, with some value added at local factories and chips getting combined with other parts before final shipment.

The White House pressed automakers, chip companies and others last month to provide information on the semiconductor crisis.

Published in The Express Tribune, October 3rd, 2021.

Like Business on Facebook, follow @TribuneBiz on Twitter to stay informed and join in the conversation.

1732569774-0/Baymax-(2)1732569774-0-165x106.webp)

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ