Karachi Students' innovative solution may revolutionise automobile industry

Automised Mirror Testing Machine can automatically test side mirrors, previously done manually, in half the time

Karachi Students' innovative solution may revolutionise automobile industry

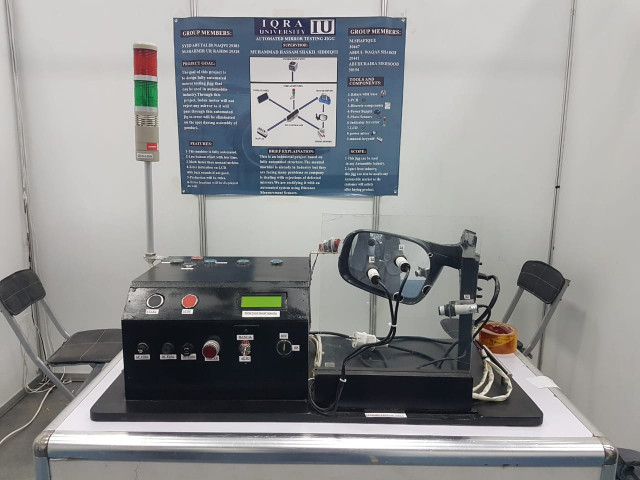

Innovation is essential for growth and change and Syed Abu Talib Naqvi, Muhammad Shamshirur Rehman and Abu Hurairah Mehboob, who are studying electrical engineering, have in a matter of nine months developed a mechanical device that can automatically test the side mirrors for automatic vehicles and trace the faults in it. The process, which is currently done manually, can now be done in half the time and through this, the production of mirrors in the automobile industry can be doubled.

The team will be presenting their project at Thailand's Stanford International University on September 7 this year.

A mentor first, musician second

Mother of invention

Naqvi told The Express Tribune that in 2017, he interned at a private company that manufactured mirrors for automatic automobiles. He observed the production process up close and was walked through each phase in the process. What stuck with him however, was the lack of a foolproof method to test the quality of the mirror.

The product is essentially composed of eight to 10 parts that have to be assembled. In the last stage, a worker has to test the fitness of the mirrors manually which is done by rotating the mirror on its axis. Naqvi shared that the process was time consuming and at the end, the company still failed to ascertain the underlying fault that caused the mirrors to malfunction. In order to trace the fault, they would further have to open each part of the assembled mirror.

Sometimes, the mirrors clear the testing phase and are sent to automobile companies for installation on automatic vehicles. There they might fail to perform in which case, the mirrors are sent back to the manufacturer that is still unaware as to where the problem lies. These rejections also reflect negatively on the company's image.

What Naqvi saw in this lacking testing procedure was an opportunity. He felt that there should be a device that could not only test the mirror's functionality but also identify and trace faults automatically. Automised Mirror Testing Machine is the outcome borne out of this need.

Made in Pakistan

The three students of Iqra University made a conscious choice to use products made in Pakistan to build the machine. Naqvi said that they could have used any of the thousands of sensors available in the market but they made it a point to use those that were not as expensive.

The sensors used in the machine are produced in Pakistan and cost around Rs1,200 to Rs1,500. Similar sensors, if imported from any other country cost around Rs3,500, said Naqvi. The indicator however, that beeps and lights up to signal the faults in the mirror, was imported from China. The indicator is not produced in Pakistan.

Similar automated mirror testing machines are in use in Japan and Korea and can be bought for around Rs2.9 million. In Pakistan, the mirror manufacturers can purchase it for only Rs150,000 which is around 20 times less than the global market price.

Stitching her way to a better life

Game changer

The Automised Mirror Testing Machine has the ability to revolutionise production of mirrors for automatic automobiles. Expounding on the benefits of the machine, Naqvi said that it takes around one minute and 10 seconds to test a single mirror manually but with the use of the machine, the task can be completed in just 30 seconds which is less than half the time. Additionally, it will help reduce the cost of labour and will prove a good deal for manufacturers.

Naqvi added that the machine can also record the number of mirrors produced in a shift.

The machine features both manual and automatic methods. Even if the automatic method ever faces an issue, the machine will remain useful.

COMMENTS

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ