Banarasi silk, made in Pakistan, has become a much sought-after commodity in the Middle East, Sri Lanka, Maldives, Nepal, Bhutan, Afghanistan and other Central Asian countries. The workers in this market have also had the honour of making the Ghilaf-e-Kaaba [black cover for the Holy Kaaba] three times.

The home-based industry employs thousands of people, most of whom belong to the Ansari community. Despite unfavourable conditions of the area, every person of the community contributes to keep the industry running.

Initially, the silk was prepared on handlooms installed at homes, which are now outdated. Mechanical weaving looms are now installed in every home in Banaras Town. The thread used to make silk is expensive and due to the low purchasing power, the cloth is now prepared from nylon, polyester and other kinds of threads. Another kind of cloth called sooti is also prepared using pure cotton threads.

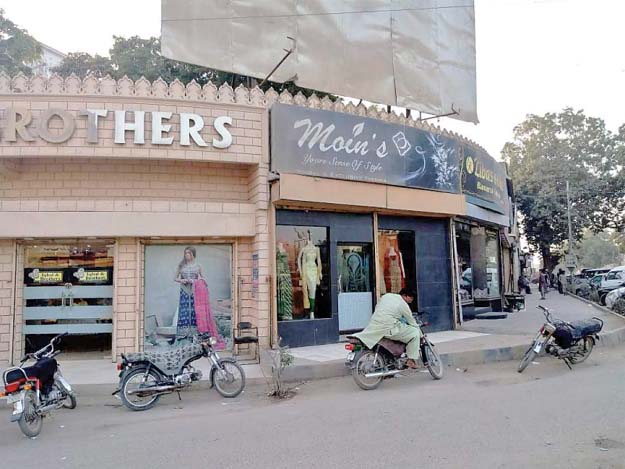

Customers’ ease

Banaras Town is located at a considerable distance from the main city area, comparatively neat and clean, free from encroachments and has free car parking for customers. Shopkeepers are known to be soft-spoken and educated. This is why the market is often crowded with families for wedding preparations. Along with Banarasi silk suits and sarees, bridal dresses are also prepared on order.

Approximately 2,000 mechanical looms are installed in Banaras Town homes. One worker operates two machines, through which he gets Rs250-400 labour charges per suit. The Banarasi silk is prepared in 10 different stages; where apart from knitting, all other nine stages are done by hand.

Currently, the fourth generation of the Ansari community is associated with the industry. They say that they have inherited their skills from their ancestors.

Under threat

Banarasi Cloth Merchant Association President Zafarullah Ansari, talking to The Express Tribune, said that the entire business of the industry depends on raw silk thread. The raw silk is imported from China and its prices have now reached Rs11,000 per kilogramme.

Ansari suggested to the federal government that the production and trade of silk cloth making should be promoted under the China-Pakistan Economic Corridor (CPEC) projects. He also requested for the installation of industries for production of raw silk in Pakistan with assistance from China.

The expertise of silk cloth production in Pakistan, partnering with the industries of silk production in China, can strengthen relations between the two countries and also play its role in reducing poverty.

Earlier, the silk imported from China was available in the range of Rs1,500-1800 per kg but in the past decade, the prices have sky-rocketed, making pure silk unaffordable for much of the lower-income class.

Looking up

But all is not lost, said Ansari. After the improvement in the law and order situation in the city, businesses in Banaras Town are gaining momentum again. Customers, who had stopped coming due to the unrest in the city, have again made their way to the market.

New designs of Banarasi silk have come in the market to match the modern taste of customers. Machine embroidery is used as it is especially liked by the customers and especially the new generation.

Ansari told The Express Tribune that the artists, designers and investors are increasingly showing interest in the silk and cotton production at Banaras Town. Huge brands are also being associated with silk production, showing signs of expansion and greater profits for the Banaras Town industries.

Published in The Express Tribune, November 16th, 2018.

COMMENTS (1)

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ