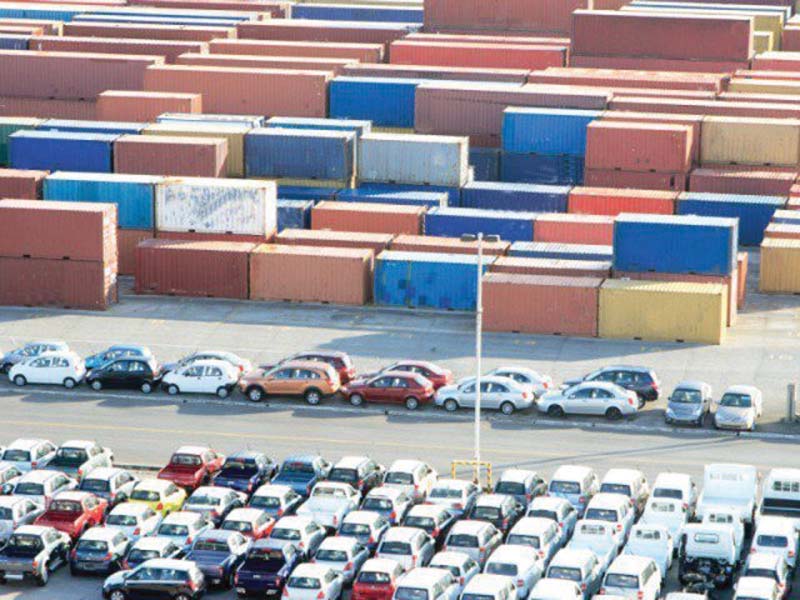

The global auto industry is highly competitive, with every manufacturer looking to race ahead of everyone else.

The fight has become especially fierce since the economic and financial crisis of 2008, and as a consequence there has been an increase in mergers, acquisitions, divestments and joint ventures merely to survive.

This has led to the emergence of certain manufacturing hubs which are better placed to meet new challenges. They are able to work on new concepts such as a flexible production line and ‘just-in-time’, which enables delivery of parts to the assembly line in a continuous flow, rather than keeping large inventories.

These innovations are making it possible for manufacturers to produce several different models on the same assembly line.

Pakistan needs to react to these challenges by overhauling its auto policy, but all indications are that no change is on the horizon. When the PML-N government came to power, it immediately set up a cabinet committee on automobile policy, led by Water and Power Minister Khawaja Asif.

After two years of deliberation, the committee has finalised its report, which is now awaiting approval of the cabinet. Although the report has not been made public, some of its recommendations have appeared in the press.

According to these reports, the auto industry is being classified into four categories: Category A is for greenfield investments (new investment by new players), Category B is for revival of existing inoperative plants, Category C is for the expansion of existing facilities for production of a new variant and Category D is for new investments by auto part makers.

The distinction of levying different customs duty rates on localised and non-localised auto parts will continue. However, for any new investments, a new category of Medium Knocked Down kits is being proposed, which would allow pre-assembled components at a reduced rate of 10% for four years.

Previously, special reduced rates were only applied to completely knocked down (CKD) engine kits.

Ignoring export-led growth

The new auto policy, like previous ones, will continue to be based on import substitution programmes rather than on export-led growth model. This implies that the assemblers will be obliged to use a certain percentage of locally made parts in the cars.

Both India and Pakistan followed similar paths for development of their auto industries, which were based on high protection through tariffs and indigenisation of cars.

However, when WTO rules on trade-related investment measures came into force, India, like many other developing countries, abolished its import substitution policies. Thus, new investors were not required to use any percentage of locally made auto parts and could source them from anywhere in the world.

As a result, the Indian car industry started flourishing. Not only the quality and environmental standards became world class, the number of cars produced increased substantially from 1.60 million in 2005 to 3.84 million in 2014.

On the other hand, Pakistan did not adjust its policies and continued with import substitution. As a result, it continued with old technology and fuel-inefficient cars.

Also the number of cars produced remained stagnant at around 150,000 units for the last 10 years and it has not been able to export a single car.

Furthermore, with all the emphasis on localisation, there has been no progress on the development of new parts as all assemblers continue to import their engine kits from their principals. The list of locally made parts has not been revised for several years indicating there is nothing new to add to the list which was compiled a decade ago.

Auto part importers claim that due to high taxes, almost 70% of local needs are met through smuggling.

Old policies failed

If the government is serious about bringing a real change in the auto sector, it should discard the old failed policies. In fact, over the years many national and international experts have been advocating such a change.

More recently, the Competition Commission of Pakistan took note of the monopolistic policies of the local assemblers and made several recommendations. However, no action has so far been taken on these recommendations.

Over the years many international auto-makers have shown interest in setting up car plants in Pakistan. But the requirement of using a sizeable percentage of locally produced parts at the outset or within a short time has made it impossible for them to do so.

Dismantle all barriers

It is critical that before implementing a new five-year policy, the government reviews earlier reports of various experts thoroughly to identify the impediments to adopting their recommendations.

In any event, it makes sense to abolish all barriers to new investments. Furthermore, there should not be any special SROs for the auto industry as this is against the declared policy of the government.

The policy should be based on export-led growth rather than import substitution. High tariffs on cars should be lowered to enable the auto industry to face some competition as is being done for other sectors.

Auto assemblers should be at liberty to import auto parts from anywhere and improve quality and reduce prices. In short, we should benchmark the auto policies with successful countries and not continue to follow outdated policies that have been abandoned by others.

The writer served as Pakistan’s ambassador to WTO from 2002-08

Published in The Express Tribune, September 14th, 2015.

Like Business on Facebook, follow @TribuneBiz on Twitter to stay informed and join in the conversation.

1719053250-0/BeFunky-collage-(5)1719053250-0-270x192.webp)

COMMENTS (4)

Comments are moderated and generally will be posted if they are on-topic and not abusive.

For more information, please see our Comments FAQ